Any reputable extractor will tell you, the most common methods of extraction and concentration are far from new. Hydrocarbons like butane, propane, and hexane have been used for food extractions since the 1970s. This is because a small number of hydrocarbons are organic solvents, capable of dissolution and dispersal of carbon-based substances — namely plant matter.

Compared to more traditional, ancestral methods of extraction (like grain alcohol or cold water), hydrocarbon extraction is technically a new science. However, hydrocarbon's efficacy in food extraction is well established. It's essentially been a part of our diet for a generation.

For users exploring the wide world of extractions, concentrates, and other non-combusting consumption methods, getting to know the ins and outs of hydrocarbon extractions such as PHOs and BHOs and what separates them from CO2, ethanol, and oil infusions is a high-minded place to begin.

What is hydrocarbon extraction?

Like any extraction process, the goal of hydrocarbon extraction is to separate essential oils from plant matter in order to concentrate the active components of the plant.

Photo by: Gina Coleman/Weedmaps

Photo by: Gina Coleman/WeedmapsImage lightbox

Simply put, hydrocarbon extractions employ cold, liquified butane, propane, or hydrocarbon blends to wash cannabinoids and aromatic terpenes from cannabis plant matter. The essential oils are then refined for recreational and medicinal use.

Hydrocarbon extraction, specifically, is notably efficient due to its negative polarity (it will dissolve some parts of the plant while keeping others intact) and super-low boiling points (-43 degrees Farenheit for propane and 30 degrees for butane). The negative polarity keeps the final extraction from featuring contaminants like chlorophyll, and the low boiling point ensures little to no solvent residue.

How does hydrocarbon extraction work?

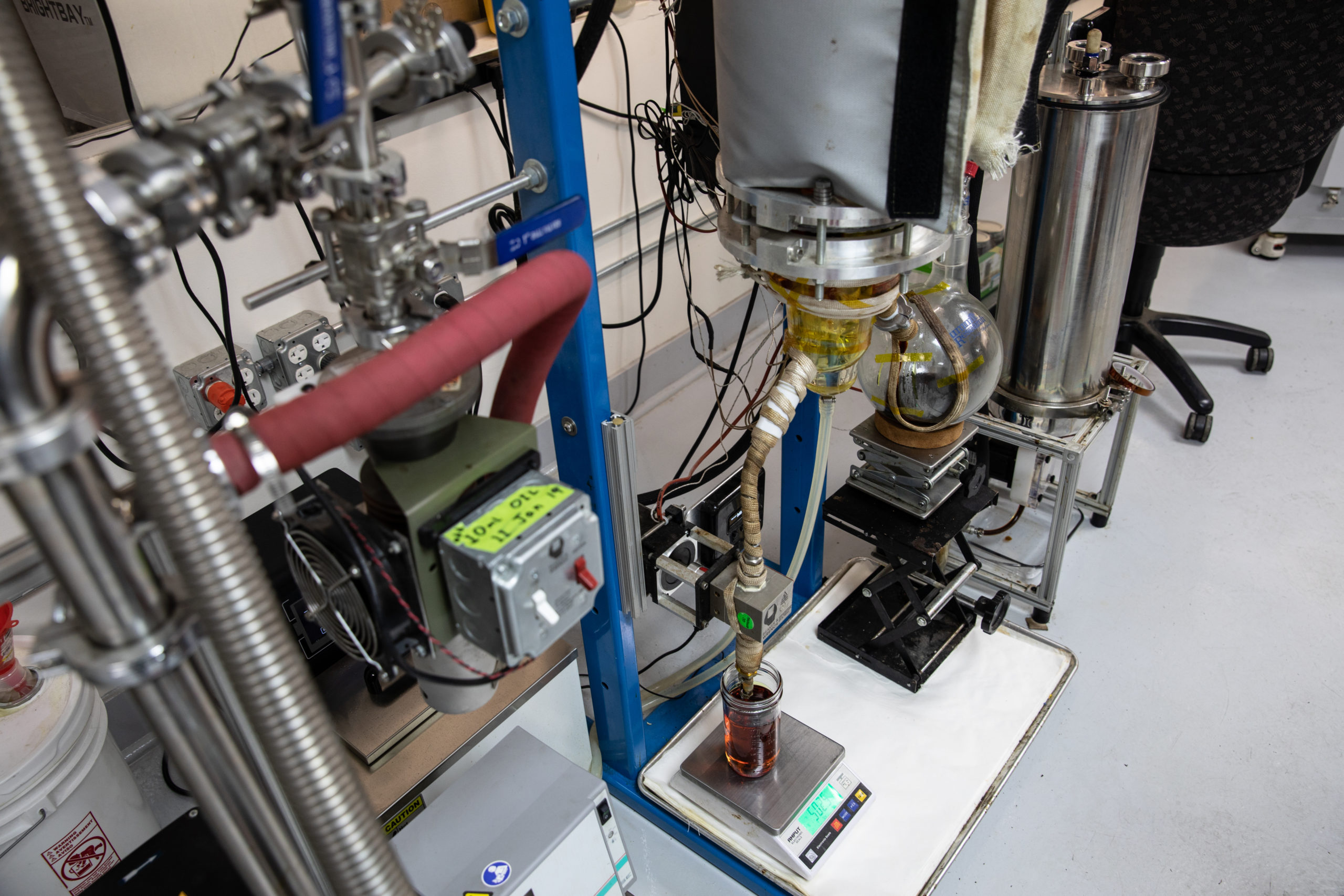

Primary extraction involves washing cannabis with cold hydrocarbons in the pressurized main chamber of a multi-chamber extractor. The waxes, fats, and lipids in the cannabis bind to the hydrocarbon, which is then separated from the plant matter in the initial chamber. Once the hydrocarbon has been purged from the extracted waxes, fats, and lipids, it can travel back to the main chamber to be used repeatedly (little to no gas escapes into the atmosphere), a system commonly referred to as closed-loop extraction.

Photo by: Gina Coleman/Weedmaps

Photo by: Gina Coleman/WeedmapsImage lightbox

While primary extraction typically results in usable oils, commercial extracts are extensively refined post-extraction to both clarify the oil and modify the texture of the finished product. This process can involve multi-step filtration, additional solvents such as ethanol, extended whipping, lengthy cooling and drying sessions, or some combination therein.

Is hydrocarbon extraction safe?

Users discouraged by the fact that hydrocarbons like propane and butane are often used as fuels and are designated volatile should keep two points in mind: volatile refers to how easily a substance will vaporize, not it's instability, and the FDA confirmed hydrocarbon extractions as GRAS (generally regarded as safe) several decades ago. And even though shatter, budder, and honeycomb dabs bear little resemblance to corn oil, they are essentially processed in the same way.

The considerable purging process for hydrocarbon cannabis extractions ensures fractional residue if any at all; and that's in addition to the more protracted post-extraction processes like decarboxylation and winterization.

Overall, the process of hydrocarbon extraction is widely considered one of the safest, cleanest, most efficient methods of extraction. These extractions are remarkably pure, with fully captured terpene profiles and the same complex combinations of cannabinoids one would find in their favorite flower strain.

How does it compare to other extraction methods?

Hydrocarbon extraction is prized for its purity and efficacy. However, the tech required to create hydrocarbon extracts is advanced, and not fit for home use. Similarly, CO2 processes produce remarkably pure, cannabinoid-rich extracts via complex, closed-loop systems that dissolve and disperse plant matter, but they too are built for mass production, not home use. These two extraction processes produce virtually identical products, and either can be argued as favorable.

The polarity of an ethanol solvent will attract plant compounds in addition to lipids, fats, and waxes. This results in a much earthier, herbaceous finished product, which many medicinal users swear by. The similarly simple process of creating rosin involves nothing more than low heat and high pressure, removing the liability of residual solvents or botanical contaminants altogether. As finished products, hydrocarbon extractions, rosins, or commercially filtered ethanol extracts can be visually identical.

In general, hydrocarbon extracts are an affordable alternative to fresh-pressed rosin. They are nearly identical to CO2 extracts, unadulterated by inactive plant matter like ethanol extracts, and available in a wide variety of textures from eyedropper tinctures to fat, greasy dabs. While making them at home might not be a stoner rite of passage, selecting your first dab pen, pen vape, or oil pen can be a watershed moment, especially for novice users primarily familiar with the lower-dose hits of flower.

Photo by: Gina Coleman/Weedmaps

Photo by: Gina Coleman/WeedmapsImage lightbox

Bottom line

Canna-newcomers, the next time you're perusing the extractions page of your local dispensary menu, consider auditioning your favorite strains as extractions rather than flowers. You too may find that hydrocarbon extractions offer an unparalleled cannabis user experience, and before you know it, you'll be carrying a vape pen with you everywhere you go.